What Makes a Bearing Corrosion-Resistant?

What makes a bearing rust?

There are many reasons for bearing rust and corrosion, and the main reasons are as follows:

1. In the process of bearing production, the bearing parts in the processing process and the finished bearing products after assembly were not antirust treated in strict accordance with the requirements of cleaning and antirust procedures and oil seal antirust packaging.

2. The quality of antirust lubricating oil, cleaning kerosene and other products used in production can not meet the requirements of process and technology regulations.

3. As the price of bearing steel has been rising, low quality bearing steel is used.

4. The storage environmental conditions are poor.

5. The packaging is not standardized, and the bearing packaging materials such as antirust paper, nylon paper (bag) and plastic cylinder do not meet the requirements of antirust packaging of rolling bearing oil seal.

MKL BEARINGS can produce different bearings far away from corrosion and rust.

stainless steel bearings

440 grade stainless steel also provides good corrosion resistance in damp environments and these are often used in the food and beverage industry where bearings are frequently washed down. Unlike 316 stainless steel however, 440 grade stainless steel has poor resistance to salt water and many stronger chemicals such as caustic cleaning fluids.

When choosing a stainless-steel bearing, 316 is certainly the most effective grade for corrosion resistance. That said, 316 stainless steel bearings are only effective if temporarily submerged. The material is much less effective when permanently submerged, unless there is a regular high rate flow of water over the bearing.

And we also can produce with 420 stainless steel bearings .

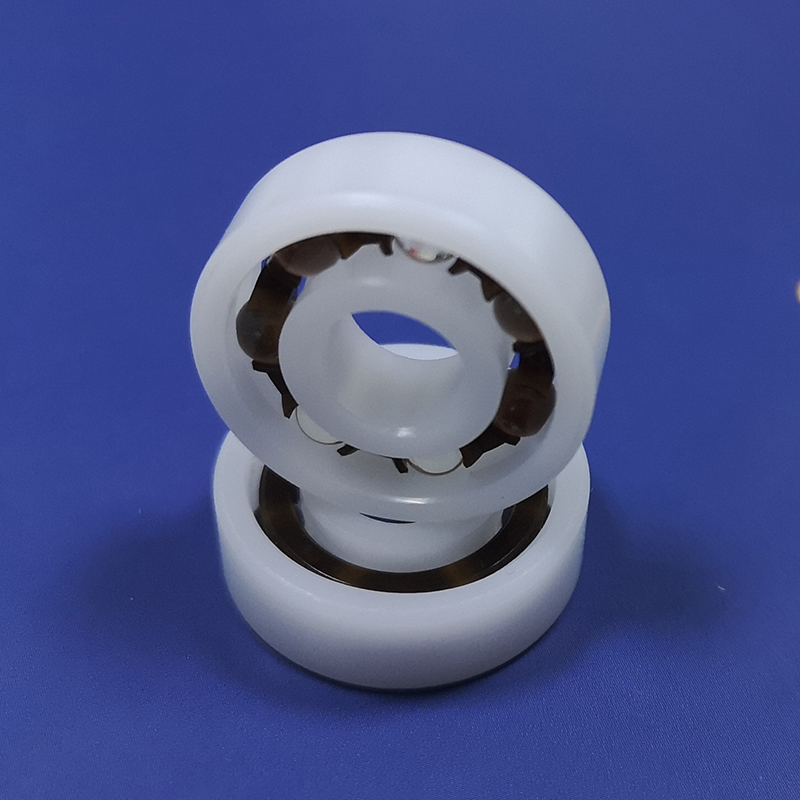

Plastic bearings

Plastic bearings provide excellent corrosion resistance, and most are also chemically resistant. These are often made from acetal resin (POM) but other materials are available for stronger acids and alkalis such as PEEK, PTFE and PVDF.

These plastics also have good resistance to chlorine and are often used in swimming pool equipment. However, these should only be used in low load and low precision applications.

Ceramic bearings

Full ceramic bearings, made from zirconia or silicon nitride with PEEK cages and seals are not affected by sea water and can therefore be used in marine environments, even when fully submerged. However, most so-called ceramic bearings are really hybrid bearings — the inner and outer rings of the bearings are made of steel, but the rolling elements of the bearing are ceramic,we can produce ceramice bearing according to your requirements .

copyright © 2024 Xiamen Miclay Imp. & Exp. Co.,Ltd... dyyseo.com

Wechat Public Number